Reading this week:

- The Banished Immortal by Ha Jin

- The Coral Sea by Alan Villiers

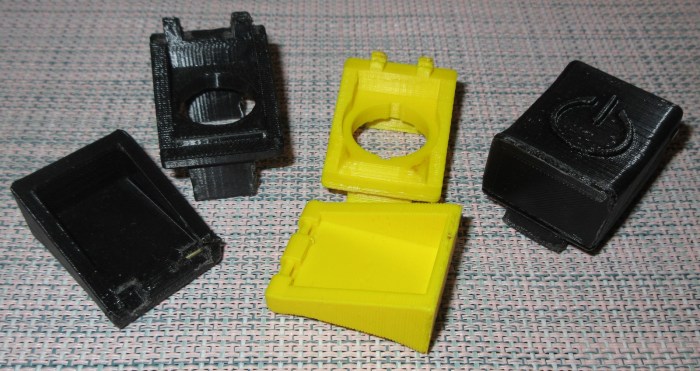

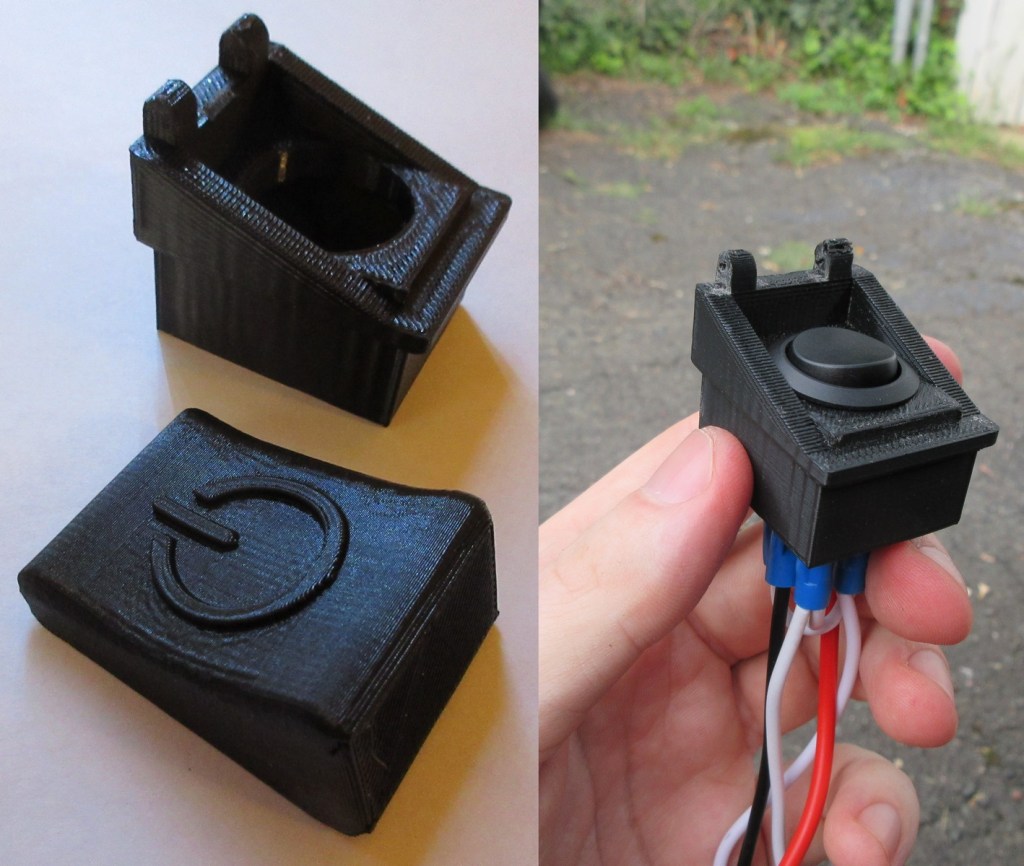

To catch everyone up, the reason this post is called “DeLorean Upgrades II” is that there is a previous DeLorean Upgrades where I installed a cutoff relay into my DeLorean. It was also my first experience with designing a part and then using a local print shop to 3D print a cover for the cutoff relay switch. That got me hooked on the power of 3D printing (i.e. a fun new toy that I could suddenly justify because going to third party 3D printing services for funky little tchotchkes you aren’t already very sure will work is unjustifiably pricey and 3D printers turns out are pretty cheap). I wound up buying the cheapest 3D printer I could find and churned out a few more iterations of that switch which has now been happily sitting in the DeLorean since then. I then moved and sold that 3D printer but then for my last birthday my parents were nice enough to buy me an upgraded printer and I have had tons of fun since printing out mostly various brackets and stands. I then decided to turn my attention back to DeLorean upgrades.

But first! Also in plastic DeLorean upgrades, years ago (and twice actually) my mom had gotten me the Lego Back to the Future DeLorean set, which is a lovely little set. But then for Christmas she got me the much bigger and much improved DeLorean Lego set. To get it my poor dear sweet mother got up in the middle of the night with her finger over the mouse button so she could scoop it up before it sold out. The little set has a lot of charm and I like them a lot but WOW is the newer one large and detailed and has a very cool mechanism for switching the wheels to flight mode and there is a nifty little thing where the flux capacitor lights up and it even comes with a beer can and banana to put in the Mr. Fusion. Size comparison between the two sets is below:

And then, just for funsies, here they are with the real deal:

One more thing before we get to the main event. The advantage of my new printer (a Creality Ender 3 S1 Pro) is that it can print much larger things. A disadvantage of the DeLorean, from some perspectives, is the lack of cupholder. In my youth I remember being able to seamlessly hold a coffee, shift, and steer all with my two hands, but these days I have gotten lazy. For a long time I thought the best location for a cupholder in the DeLorean would be in the passenger side knee pad, as part of a flip-down latch mechanism. The biggest thing preventing me from doing that is that I would have to either cut a giant hole in my current knee pad or else make a new one. The first is a regrettable thing to do to the car and the second is beyond the capabilities of my current set of tools. I realized though that the console tray would fit on my printer bed and is easy to swap out without causing permanent damage to the car. I tried to design a sleek pop-up mechanism for a cupholder that would normally be hidden, but wasn’t satisfied with any of my designs. Then it dawned on me I could design just a normal cupholder, so that’s what I did:

I printed the above version pretty rough n’ ready just to test it out. I need to go on a long car trip to see how it works in practice and then maybe I can refine the design. I realize putting a cupholder in the DeLorean is blasphemy, but sometimes you just have to become an iconoclast. Sorry.

This brings us to the speedometer. The DeLorean has a well-documented design flaw where the speedometer tends to break due to some weaknesses in the linkages. I have generally learned to live with this and it has been a very tiny minority of the time of my owning the DeLorean where the speedometer has actually worked. You just gotta know about how fast you are going based on the tachometer and the gear you’re in. There are improved linkage parts available, and I think I have those actually but then I was driving somewhere north of 85mph (max speed on the stock speedometer) and the speedometer failed again and I didn’t want to bother to fix it (to the chagrin of my fiancée). Then I hit the idea to install a GPS speedometer.

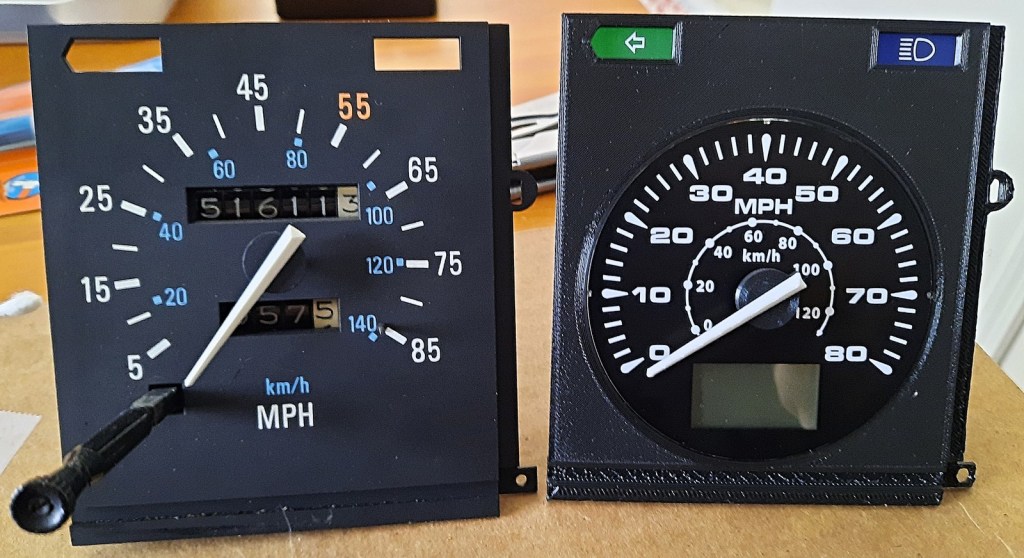

My dream, if I ever had the time, money, and inclination, would be to swap out the instrument panel on the DeLorean entirely. The stock one is fine but I think what the DeLorean really deserves is a digital display like they were doing back in the ’80s on concept cars. What I have had in mind for years is something like the Nissan NRV II, but that is vastly beyond what I am going to achieve anytime soon. When I was poking around for GPS speedometers online that I could buy I was hoping for something digital I could use, however I didn’t find anything in the right form factor. I also briefly considered just sticking a digital GPS speedometer on top of the instrument cluster, à la the movie, but decided with a broken analog speedometer that was just silly. And finally since I didn’t want to spend a ton of money on a GPS speedometer there was a goodly chance I was just going to break, I opted for the cheapest one I could find on Amazon. Actually there are cheaper ones still, but I decided I wanted the odometer display, and I wanted the faceplate to somewhat match the stock speedometer.

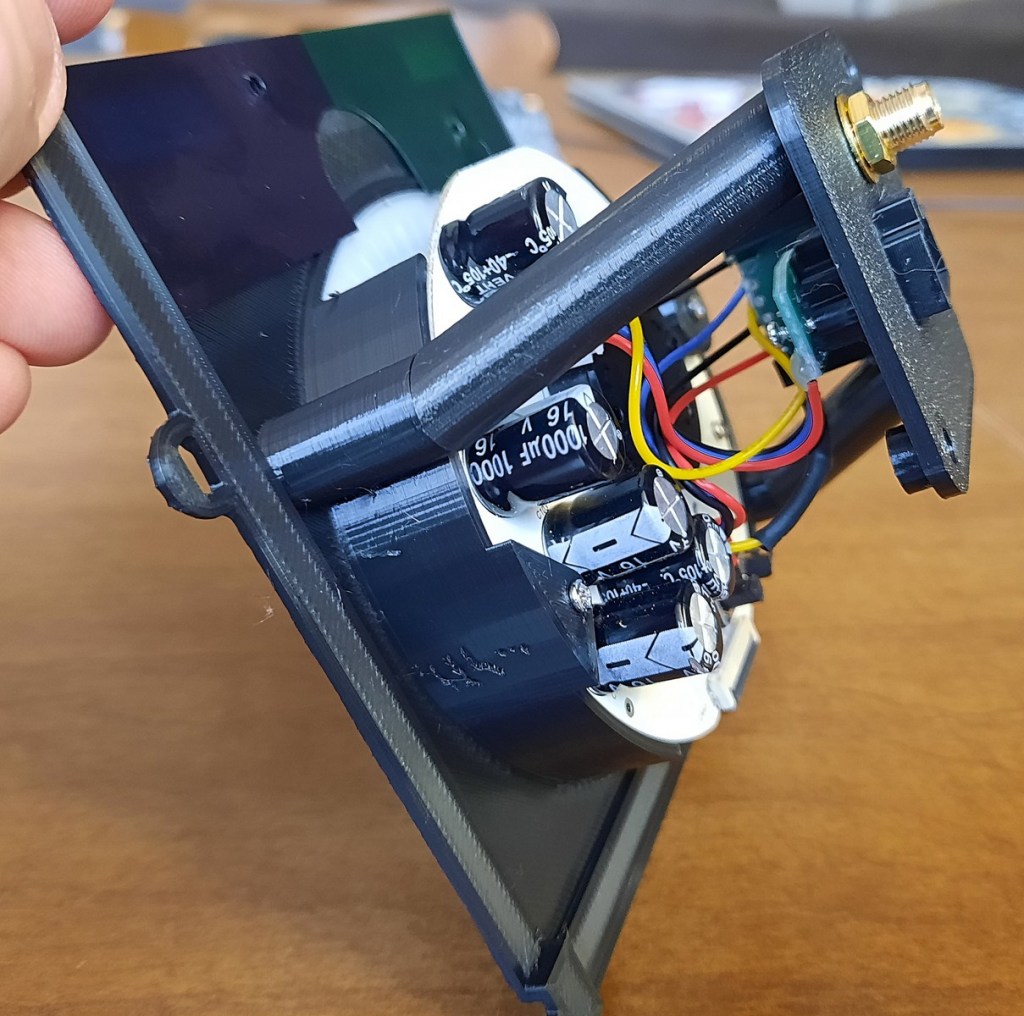

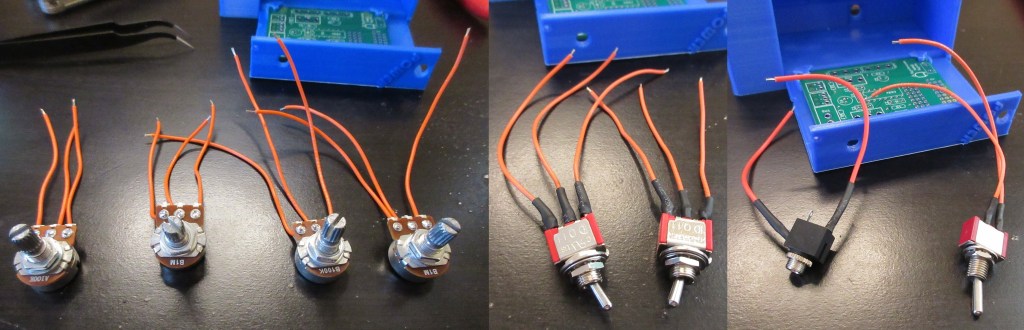

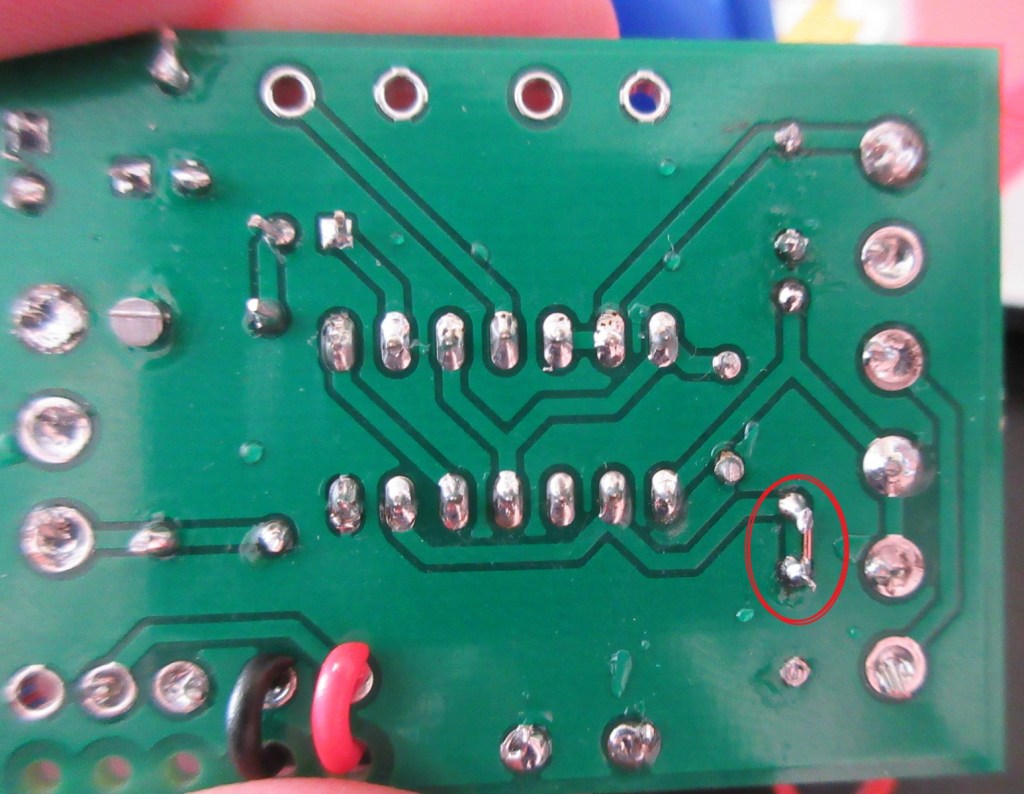

Next step was figuring out how to install it. The speedometer comes in a rather hefty plastic housing that is meant for you to just stick into an appropriately sized hole in a piece of sheet metal or similar. This housing is too big to just stick into the instrument cluster, even if it wouldn’t look terrible, so my plan all along was to remove the innards from the housing and see if I could more elegantly integrate them into the panel. Taking it apart was annoyingly difficult. To get the glass cover off you had to loosen and then pry off that metal ring around it. The rest of the disassembly would have been a lot easier if I had realized what the blue rubber covering the mounting screws was, so I wound up using a rotary tool I bought for the occasion to crack that oyster open (as you can see above), only slicing through one wire in the process which I later soldered back together.

I had been hoping that the guts of the speedometer would be smaller than the faceplate, but the circuit board is the same size. Because of this, there is only one position that it fits into the instrument cluster. I considered for a while using my new rotary tool to do some surgery on the instrument cluster, but for the sake of not doing irreparable damage to a several hundred dollar part decided against it and just had to live with the new speedometer being a little out of line. Then the next step was designing a housing for the GPS speedometer that would let it be installed into the DeLorean instrument cluster. This would have been a lot easier if I ever got around to learning how to actually do 3D modelling, which I keep planning on getting around to. This is why the below design is less than elegant, but it works. The speedometer is snugly secured to the front panel, which replicates the size and shape of the stock panel and lets it get installed into the cluster. The external wires that the speedometer needs (power and GPS antenna) are routed through the back panel. I made those bits fiddlier than they needed to be but I had an urge to get fancy. The back panel also helps secure the new speedometer unit into the instrument cluster. I wound up cannibalizing from the stock speedometer the colored plastic for the indicator lights (I just used double-sided tape to mount it in place) and the two bolts that held the speedometer in the back, but those can be easily re-installed into the stock speedometer. To keep the stock speedometer safe in storage I printed up a custom box for it where it will be very snug. Below is the end result of all my modelling, prototyping, and printing. It isn’t perfect (it could be prettier and the speedometer is actually sliiiiightly off from vertical), but it works and I decided to install it to road-test it before trying future iterations. Plus I had to take my cat to the vet the next day (the DeLorean is my only car) and I needed to wrap this project up and reinstall the instrument cluster.

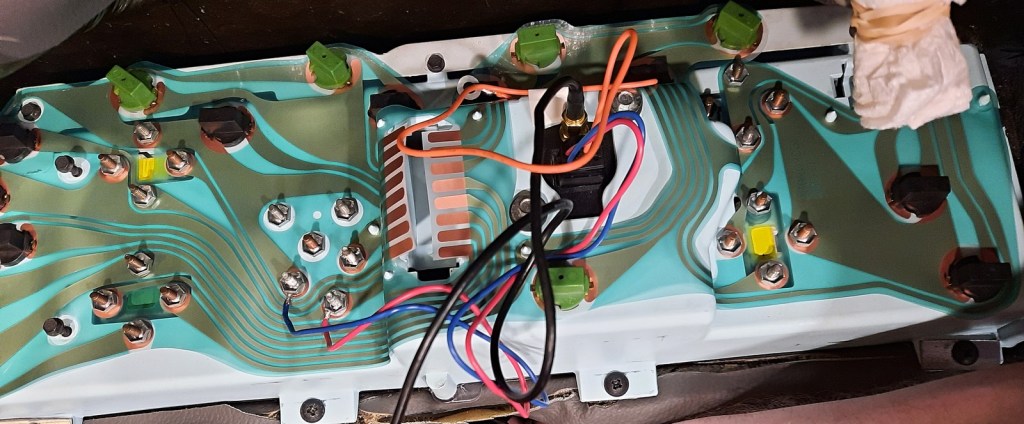

Once the new speedometer was bolted into place I reassembled the rest of the instrument cluster. Since I had bothered to remove the cluster from the car (which is a supremely annoying task, as is doing anything else on the DeLorean) I replaced the flexible circuit board in the back along with some bolts and washers. The GPS speedometer of course requires power and I figured the easiest thing to do was to wire it into the +12V and ground wires for the tachometer, hoping that doing so wouldn’t take out both instruments. I almost wired it in backwards but decided to double-check the wiring diagram. The picture below is of the back of the instrument cluster with the speedometer installed and wired up, a picture which I remembered to take only in the elevator on the way down to the car. The orange wire is for the speedometer’s backlight, which I eventually realized I had no convenient way to wire in and would have not jibed with the rest of the panel. As you can barely see the GPS antenna is also connected in the below picture. I routed the cable underneath the dashboard and placed the antenna itself on the dashboard, secured with some more double-sized mounting tape. It’s visible but relatively discreet.

And finally below we have the speedometer installed into the instrument cluster and working great! It’s obviously not the stock speedometer but I don’t think it looks too bad in with the other instruments. A last-second change I made which I think helped enormously was to replace the dial. The one that came with the GPS speedometer was red and designed to be backlit at night. I quickly printed up a new one that matched the other dials and it helps the GPS speedometer blend in a lot. I am very happy with the look. There are improvements to be made in the next round, and if I had the money the thing to do would probably be to figure out how to get a GPS speedometer where the servo for the dial is separate from the circuit board so I could place it better, along with making an entirely custom faceplate that matches the stock one. But this is for the future.

One decision I didn’t mention above was to get a speedometer that only goes up to 80. The stock speedometer goes up to 85 and it is an available upgrade to get one that goes up to 140. The nominal top speed of a DeLorean is something like 120, and I have bottomed out the stock speedometer plenty of times, so a larger range could have been useful. There are GPS speedometers that go higher but I decided granularity at lower speeds would be better. And there is no risk of this one breaking if I do exceed 80.

I am really happy having installed the GPS speedometer. It was a fun use of my 3D printer and added some good functionality to the car, namely a working speedometer. It takes the unit a minute or so to find the satellites after I exit the parking garage, and the speed lags half a second or so, but that’s easy to live with and a big upgrade from no speed indication at all. I am also really glad I did this project because the instrument cluster was developing other problems (indicators not working, lights going out) that were from the circuit board getting old, so now those have cleared up and have really improved the driving experience. I am looking forward to the next 3D printing project on the car!

You must be logged in to post a comment.